What is machine control?

Precision and productivity

For any earthwork contractor, it is important to perform work with quality, precision, and on schedule. Utilising machine control in work machines enables optimising the different phases in the earthwork process, from planning all the way to the upkeep phase.

The excavator’s machine control system guides the machine operator in attaining the target plane quickly and easily. When the job is carried out properly the first time, you can save time, materials, and fuel. The increased productivity gained thereby shows in improved work profitability.

3D machine control

When using 3D machine control, no staking-out is needed. The site elevation information is always present in the bucket tip, and there is no need to set up lasers or stakes. The three-dimensional design models are always visible on the system display, which helps the operator to handle even the most challenging sites effortlessly.

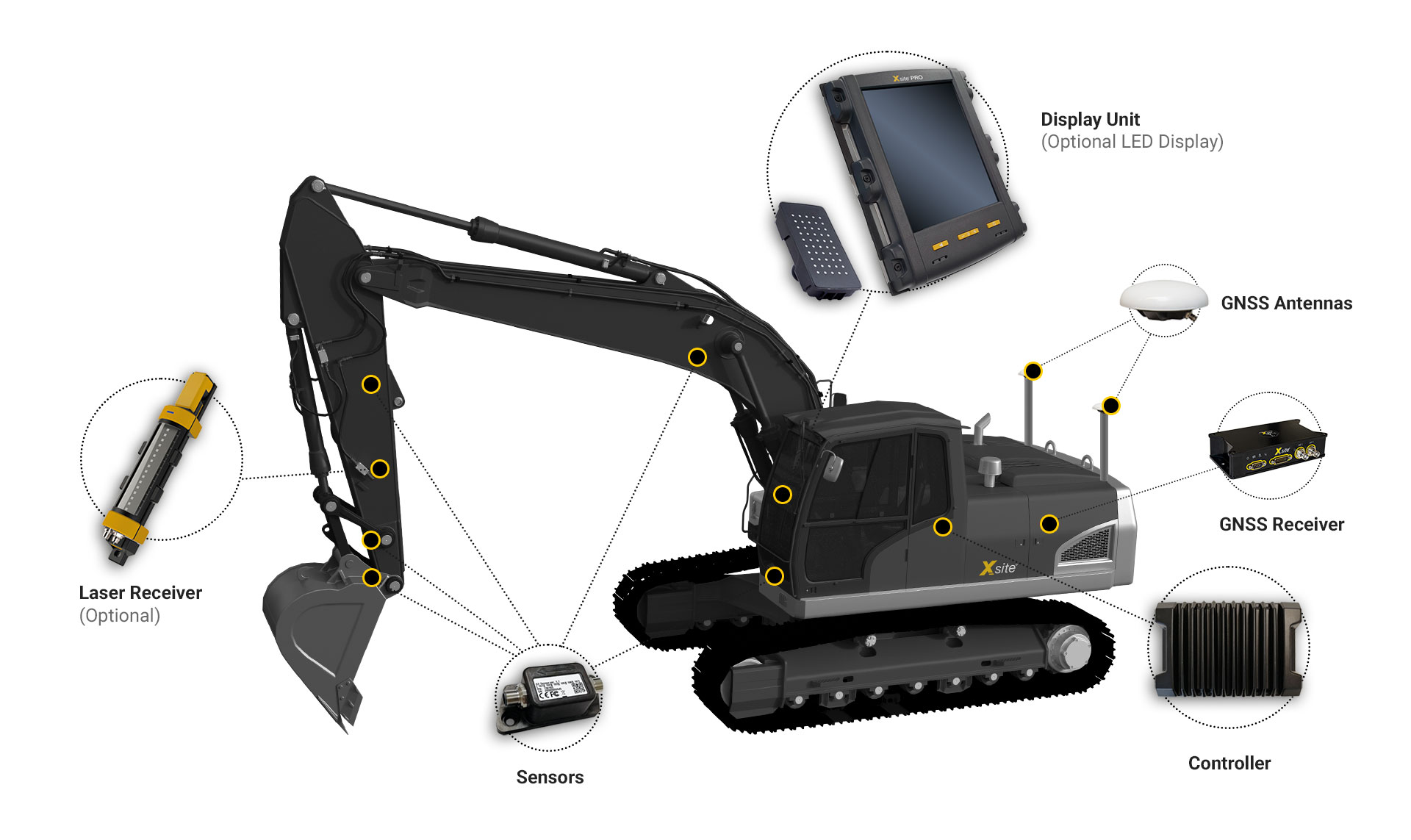

The excavator’s 3D machine control is based on RTK-GNSS satellite positioning. With the help of a correction signal produced by a base station or network service, centimetre-level accuracy can be achieved with the machine control system (+/- 2cm). With 3D machine control, the machine itself becomes a highly accurate measurement device.

Want to learn more about 3D machine control? Visit our product site for more information!

Benefits of machine control

- The work gets done more efficiently and quickly as the operator can concentrate on productive work. Less time spent on the contract means cost savings in employee, fuel, and machinery expenses.

- The accurate measurement device enables tighter tolerances. No excess cutting or filling. Material and transportation costs decrease as the use and transportation of extra materials are no longer needed.

- Higher accuracy leads to more uniform work quality throughout the contract. Machine control turns a good machine operator into a great one!

- Improved jobsite security, as surveying close to the machinery at work or in the excavations is reduced.

- The system guides the operator in all weather conditions and, therefore, making the work easier especially under poor conditions, such as rain or darkness.

- The location information of the machine is based on RTK-GNSS positioning, so there is no need for staking out. Working becomes independent and fluent as you don’t have to rely on surveyors or stakes – or the lack of them.

- As-built data can be saved by using a bucket as the surveying tool. The completed work gets documented and the documents sent to the office for further processing.

Read more about the benefits from our product site!