Tech Blog: European Innovation and Leadership – Novatron took machine control to the next level

October 17, 2024

Discover what makes Novatron a pioneer in components and machine control systems. Over the past 30 years, Novatron’s machine control systems have evolved significantly. A major breakthrough occurred in the early 2000s when the company introduced the first 3D machine control system featuring a graphical user interface and advanced sensor technology.

Novatron’s machine control system, the first generation of modern Xsite, was a groundbreaking innovation and a leader in its field, setting an example that many competitors have since followed. Mikko Vesanen began working at Novatron in the early 2000s. His responsibilities at the time involved developing mechatronic systems—devices that combine robotics, intelligent sensors, and microprocessors.

Now serving as the Director of Software Products, Vesanen recalls: “I can confidently say that in the early 2000s, we had the first 3D machine control system with a graphical user interface, which already operated with the Windows-based modeling tool.” Since no similar systems existed at that time, Novatron, with a team of fewer than ten people, had to develop everything from scratch, including the components.

“We are a unique company because we create everything in-house,” Vesanen adds.

“Our experts’ deep understanding of positioning technology and the kinematic models of machinery has been a key factor in ensuring the accuracy and efficiency of our sensors and software,” – Mikko Kipinoinen, VP and Research and Development

When designing high-quality sensors, many things must be considered, such as the vibration of work machines and large temperature fluctuations. Novatron’s new G3 sensors are ten times more efficient than their predecessors, the G2 sensors.

The harsh Nordic climate pushed innovation forward

Construction conditions in the Nordic countries are significantly more challenging than in other parts of Europe. In Finnish and Nordic construction, factors like rock cuts, the effects of frost, and complex road and tunnel structures demand more from modeling and machine control systems. As early trials in Norway demonstrated, the components developed by Novatron had to withstand the harsh working conditions and vibrations from machinery.

Vesanen notes: “Developing the components for machine control systems was not an easy task. The product components must endure machine-induced vibrations and climate variations while providing centimeter-level accuracy.” The concept of these components and technology might never have been developed in a country with mostly sand terrain.

“From a mechatronics perspective, we’re agile. If an issue arises in the field, we can fix it quickly and implement changes in the next release within a week” – Mikko Vesanen, Director of Software Products

Mikko Kipinoinen, Novatron’s VP and Research and Development, is responsible for components’ high performance.

“In product development, we focus particularly on system durability, reliability, and user-friendliness because the systems are used in environments where errors can lead to serious consequences. Quality is a key factor at every stage, and the systems undergo comprehensive testing in various conditions to ensure they can withstand demanding field environments. The Nordic setting ensures the system is tested in the most challenging conditions”, Kipinoinen adds.

Novatron’s components strongly reflect their European origins. Only a few components come from elsewhere, such as the United States. Most critical innovations, like mechanical parts, are designed at Novatron and manufactured in-house or by strategic partners in Europe. This ensures consistent product quality and shorter delivery times, which is crucial when introducing new solutions into production.

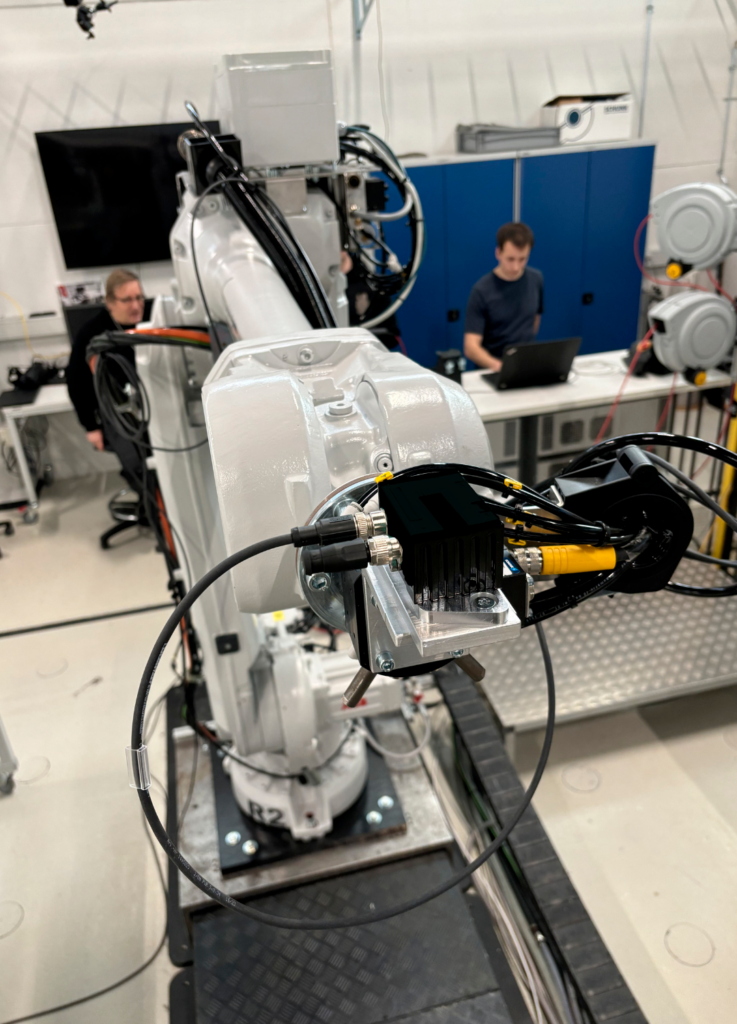

Novatron collaborates with various universities on research as part of its product development. The studies investigate the movement profile of the different sensors on the market and how effectively Novatron’s sensors perform in relation to them to ensure competitiveness and fulfillment of the customer promise. (Photo: Tampere University)

Safe and sustainable pioneering work

Novatron’s IMU sensors have always been critical to the system’s efficiency. From the beginning, the company has prioritized designing and manufacturing components in-house in Finland. Locally produced components and assemblies allow quick responses and solutions to problems, which is crucial in an already fast-paced customer environment.

Jesse Kettunen, Head of Machine Control Hardware Development, highlights Novatron’s collaboration with universities in developing and testing sensors.

“We have actively worked with institutions like Tampere University. During the development of the G3 sensor, tests conducted with the university showed that the sensors maintained high accuracy during fast movements and sudden stops, with latency (the round-trip delay of data) remaining under 10 ms, even in varying conditions”, Kettunen says.

One significant technological innovation Kettunen highlights is the shift from analog to digital sensors. “In our current sensor, we chose digital over analog sensors, which allows for better development of filters and algorithms and frees up bandwidth for the microcontroller’s performance,” Kettunen explains. This decision enhances the sensor’s performance and helps make the system more intelligent and efficient. For the user, this translates to increased system reliability.

“Our experts’ deep understanding of positioning technology and the kinematic models of machinery has been a key factor in ensuring the accuracy and efficiency of our sensors and software,” adds Kipinoinen.

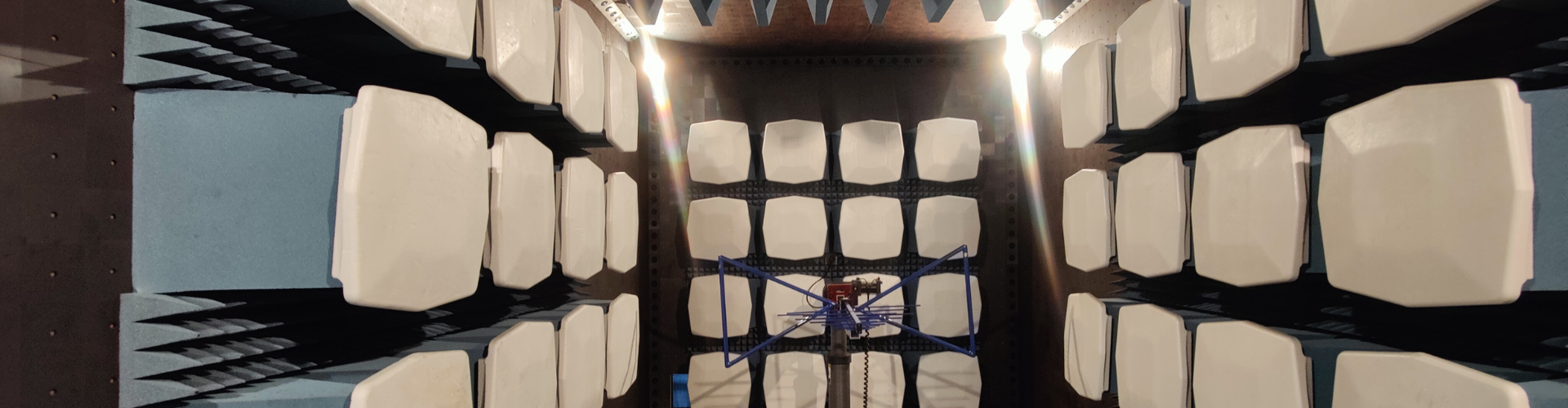

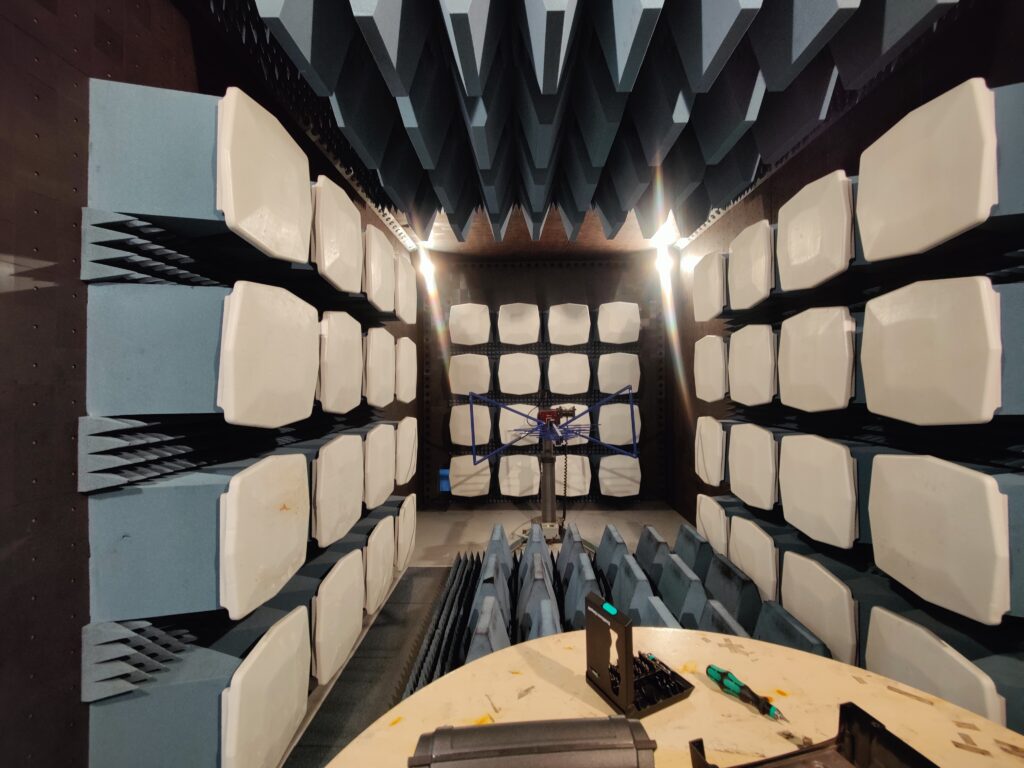

Novatron’s product development has utilized Tampere University’s EMC chamber to test current components’ FCC (US frequency standards) profiles for radiation. (Tampere University)

High-quality service supports high-quality products

Novatron’s strength lies in its technology, deep understanding of customer needs, and effective use of feedback in product development.

“Customer feedback and user experiences have played a central role in the continued development of both software and mechatronics. Product managers and owners are in constant contact with customers,” Kipinoinen explains. As part of Novatron’s quality system, feedback is regularly collected through remote support customer satisfaction surveys.

In developing its products, Novatron works closely with test operators to quickly gather improvement suggestions and feedback. “From a mechatronics perspective, we’re agile. If we notice an issue in the field, we can fix it quickly and implement changes in the next release within a week,” Vesanen adds.

According to Vesanen, customer feedback has significantly decreased over time as the company has accumulated years of knowledge about all possible scenarios and issues. Understanding customer needs has helped shape products to be more user-friendly, and direct connections to worksites remain a vital part of product development.

In developing its products, Novatron works closely with test operators to quickly gather improvement suggestions and feedback.

Future Integrations and Technology Compatibility – European Expertise as a Competitive Advantage

Novatron’s sensors support common data transfer protocols, allowing easy integration into partner applications and creating a seamless and efficient workflow on construction sites. From the start, Novatron’s values and operating philosophy have emphasized open interfaces, enabling customer-centric solutions and driving industry development. Unlike many competitors, the Finnish Novatron believes in a win-win strategy with its customers and end users.

“Finns are known globally for their integrity and straightforwardness,” Kipinoinen notes.

Novatron is actively involved in defining international ISO/DTS 1514-4.2 standards. For example, the company plays a key role in promoting the use of data models in construction site processes. It is closely involved in drafting the next international ISO standard, which is set to be released on February 2, 2025.