Blog: Open BIM in infrastructure industry

September 15, 2016

This article describes the significance of open Building Information Modelling (open BIM) on the productivity of the earthworks industry. The productivity of the infrastructure industry can be improved by promoting and furthering the implementation of building information modelling and open interface based data systems.

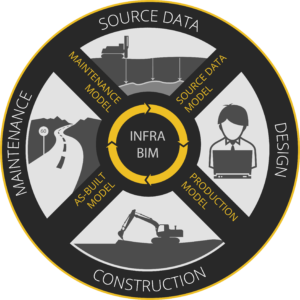

Information modelling means a process based on an information model that permeates all stages of the project. The information model consists of information from the whole life span of the project, stored digitally in a commonly agreed format. Data/information is collected as the project moves from one stage to the next, also resulting in proper documentation of construction and maintenance works.

Different work stages of an infrastructure project

An information model is more than just a three-dimensional drawing

Compared to traditional paper drawings, a 3D model in a digital format makes it easier to perceive the project being worked on. However, easier visualisation and perception are not the only benefits of information modelling. Quality control during the planning phase is another example of the benefits. In addition to traditional visual checking, collision detection can be carried out on the information model. This would show, for example, whether information technology cables and water pipes can be installed as they have been planned, or whether they have accidentally been planned to collide with each other. The costs of rectifying such planning collisions in the model are lower the earlier they are discovered; mistakes that are only discovered during construction cost significantly more to rectify than those discovered while still at the planning stage.

Towards open and compatible systems

Achieving the full benefit of information modelling requires the use of tools that support information models in every phase of infrastructure construction. Information technology is already widely in use on many construction sites today; construction machines make use of satellite positioning, touch-screen computers direct the work of operators, and site supervisors can follow progress at the site via mobile devices such as tablet computers. Design models and as-built data move wirelessly between the office and the site. In an ideal scenario data moves easily from one phase to the next and different systems communicate seamlessly by speaking the same common language.

There is still room for improvement in the transfer of information. Many system manufacturers have their own closed database formats which are not compatible with others. Open interfaces and compatible data systems are of key significance in ensuring information flow through the whole project, from planning through to maintenance. Systems that support open interfaces are able to read and, more importantly, interpret material from the previous project phase correctly. Initially collected source data is transferred to the planning stage and from there to the construction and maintenance phases. This forms an unbroken chain where data moves seamlessly from one phase to the next.

Information modelling from the machine operator’s perspective

Machine control plays a significant role in information modelling based construction. If the planning office speaks a language that the machine control system understands, the machine operator sees the project on the control system screen just as the designer has intended it to be seen. The system guides the operator to achieve the right height and level without the need for stakes in the ground. Working without reliance on stakes leads to greater working independence for the operator. Accurate planning information on-screen also makes work in difficult places possible, making work more effective and minimising the risk of mistakes.

The excavator operator can see the position of the bucket and the design model on his screen

Furthering information modelling

Simply adopting tools that support information modelling will not ensure that information modelling becomes common within the industry; co-operation between industry players is also necessary. Finland is an example of a country where efforts to improve data transfer have been made already for many years. Many parties in Finland have joined forces to develop the LandXML-based InfraModel3 data transfer format (IM3). As a common standard, IM3 helps the transfer of information from one phase of the earthworks project to the next and from one information system to another.

In future, work to further the use of information modelling in the infrastructure industry will be led by the buildingSMART organisation. Machine control systems manufacturer Novatron is also participating in the work of buildingSMART Finland, supporting the implementation of the InfraModel3 standard and furthering compatibility and communication between information systems. Novatron’s aim is to help improve productivity in the infrastructure construction industry by making the benefits of machine control systems with support for open standards available to everyone in the industry. Information modelling and the tools that support it make it possible to lift productivity to a whole new level.